HACCP restaurant - Hygiene in the kitchen

How not to throw in the towel when faced with the difficulties of implementing a Restaurant HACCP Plan? In this article, we will give you some essential keys to make this process easier for you.

But first of all, what is catering hygiene?

L’hygiène correspond à un ensemble de mesures et d’actions visant à réduire au maximum les risques de contamination. Ces contaminations peuvent être dues suite aux manipulations des denrées alimentaires, aux mauvaises conditions de stockage, ou encore au manque d’hygiène des locaux et du personnel. Afin de minimiser au maximum ces risques, en France la loi impose aux restaurateurs de mettre en place un plan de maitrise sanitaire. Pour pallier l’ensemble des risques sanitaires, plusieurs mesures doivent donc être mises en place par les dirigeants pour éviter tout risque d’intoxication alimentaire (HACCP Restaurant).

Free Trial | Koust Application

Il est notamment question de contrôler la qualité des produits alimentaires reçus, de mettre en place des systèmes de nettoyage (locaux et personnel), d’être équipé de matériel de production et de stockage adaptés et entretenus, de sensibiliser le personnel au respect des mesures d’hygiène mise en place par la direction, etc.

The HACCP restaurant standards to be respected

There are a number of regulations governing food hygiene and restaurant owners are obliged to implement a Sanitary Control Plan (SCP).

Restaurateurs are therefore obliged to comply with the food hygiene regulations in force.

There is, however, a distinction between commercial and contract catering.

The health control plan

The food safety control plan is a tool for maintaining an acceptable level of food safety at each stage of storage or production.

To help restaurateurs in this process, the GBPH (Guide to Good Hygiene Practices) and the HACCP (Hazard Analysis Critical Control Point) method are essential.

Mise au point par la Nasa en 1959, la méthode HACCP a été pensée pour éliminer ou réduire à un niveau acceptable tout danger, qu’il soit d’origine biologique, physique, chimique ou allergène. Aujourd’hui, cette méthode est unanimement reconnue comme une démarche fiable et performante pour maintenir la sécurité sanitaire dans tout type de production alimentaire.

The disadvantage of the HACCP restaurant method is that at first glance it does not seem easy to implement. Here we will give you the keys to successfully implementing this method in your restaurant.

Implementation of the restaurant HACCP tool

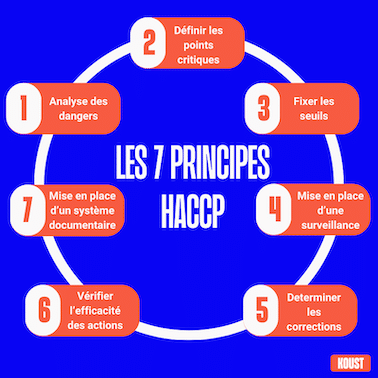

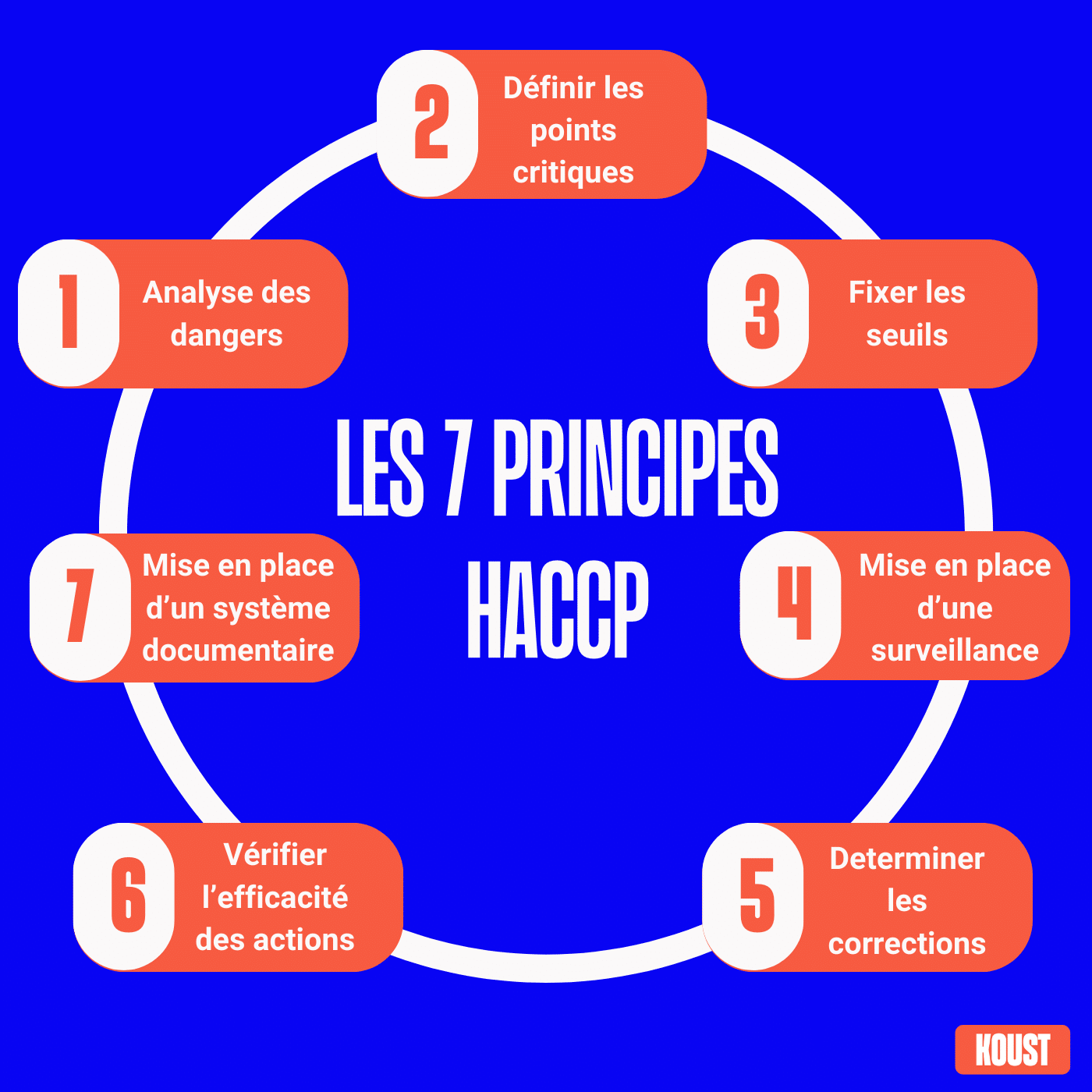

The HACCP method is based on 7 principles, these are :

- Conduct a hazard analysis.

- Identify critical points.

- Define critical thresholds.

- Set up a monitoring system for critical points.

- Determine the corrective action to be taken when monitoring reveals that a critical point is not under control.

- Check the correct operation of the HACCP method implemented.

- Establish a record of all procedures and records performed.

Before putting it into practice, let's look at the different types of hazards:

- Biologiques : bactéries pathogènes, toxines, parasites.

- Chimiques : Produit de nettoyage insuffisamment rincé, contaminant les aliments en contact avec les surfaces, les produits de lutte contre les nuisibles.

- Physiques : les corps étrangers. Morceaux de verres ou de plastiques présents de manière accidentelle dans les préparations alimentaires.

- Allergènes : Les identifier, et les recenser dans chacun de vos plats. Un restaurateur à l’obligation de déclarer une liste de 14 allergènes sur demande de la clientèle.

Let's put the HACCP restaurantplan into practice

1. Conduct a hazard analysis

- Breaking the cold chain.

- Storage temperature not controlled in positive cold room (meat).

- Alteration of a food due to abnormal microbial development = Biohazard.

2. Determine critical points

- La température doit se situer entre +1 °C et +3 °C.

- Un écart occasionnel de 2 degrés est toléré, mais doit rester exceptionnel.

3. Define critical thresholds

- Atteinte d’une température de 0 °C.

- Atteinte d’une température de +5 °C.

4. Establish a system for monitoring critical control points.

- Contrôler une fois par jour la température des chambres froides.

- Enter the results in an appropriate document.

5. Determine the corrective action to be taken when monitoring reveals that a critical point is not under control.

If the critical threshold is reached :

- Check the correct temperature display with another thermometer.

If the temperature is confirmed:

- Enregistrer la valeur et ajuster la température de la chambre froide pour revenir à la valeur cible située entre +1 °C et +3 °C.

- Vérifier la qualité des produits en stock et traiter les non-conformités telles que décrit dans le document “traitement des non-conformités” page…

- Check again 30 minutes after adjusting the temperature to confirm the effectiveness of the corrective action.

In case of different values :

- Contacter immédiatement le service de maintenance pour intervention et ajuster la température de sorte à atteindre la valeur cible située entre +1 °C et +3 °C.

- Verify the quality of the products in stock and deal with non conformities as described in the document "treatment of non conformities" page).

6. Verify the proper functioning of the restaurant HACCP method.

- At the end of the month, check the presence of the records (temperature readings) for each day of the past month.

- Conduct random additional temperature self-checks.

- Questionner le personnel afin de confirmer leur connaissance des seuils critiques et mesures correctives pour savoir s’il y a un besoin de formation sur ce point. En effet, la formation Hygiène alimentaire est une exigence incontournable pour les professionnels de la restauration. Elle vise à assurer la maîtrise de la méthode HACCP et à permettre son application judicieuse au sein de votre établissement. En suivant cette formation, vous serez également en mesure d’anticiper les risques alimentaires en identifiant les dispositifs de contrôle indispensables à mettre en place dans votre établissement.

7. Establish a record of all procedures and records performed.

- Create a file containing the temperature control procedure, the procedure (corrective measures) to be applied if a critical threshold is reached and all temperature records (recordings).

- Provide staff with the necessary recording documents for temperature checks.

- Make available to the staff the documents relating to the control procedures (temperature reading, critical threshold and corrective measures).

- Conduct HACCP training to ensure your team understands the implementation of the PMS for food hygiene.

This is an example of the reasoning for all the hazards identified. You can do this work via a table. Start by making the list of hazards in step 1, once done, perform steps 2 to 5 for each of them. Finally, complete steps 6 and 7. Here is an example HACCP table Restaurant under Excel.

I invite you to consult and implement the PMS carried out by the UMIH (Union des Métiers et des Industries Hôtelières). It is simple and concrete, it is a good document to start and implement a PMS. Download the PMS

Également, voici une vidéo réalisée par cinq étudiants dans le cadre de leur projet d’étude à l’IUT Génie Biologique de Saint-Brieuc. Bien réalisé, pédagogique, elle est une source d’information utile !

The new digital tools

L’application d’un plan de maitrise sanitaire est une démarche complète qui demande anticipation, organisation, suivi, mise à jour, autocontrôles et enregistrements. Pour simplifier la mise en place d’une méthode HACCP et le suivi du plan de maitrise sanitaire, le digital s’est mis au service des restaurateurs en proposant des applications complètes permettant de mettre en place efficacement un plan HACCP. Ces nouveaux outils regroupent l’ensemble des fonctionnalités de traçabilité et d’hygiène alimentaire nécessaires au maintien de votre PMS. De plus, en cas de contrôle, vous pouvez justifier de la bonne gestion des risques sanitaires dans votre/vos restaurant(s). En effet, un outil HACCP comme celui de Koust permet de justifier du bon suivi des principes d’hygiène et traçabilité alimentaire.

To discover our hygiene solution, take a free trial. It applies to all types of catering, and also gives you access to management and margin control functionalities!